300% Process Acceleration – SIKO’s retrofit solution optimized double-sided format and edge banding machine from HOMAG

EUROTEC is a distributor and specialist for used woodworking machinery. The company’s core competence is the retrofitting and reconstruction of precision transport chains for combination or edge banding machines and double end profilers. In its most recent project, a double-sided format press and edge banding machine of the type HOMAG KF20/22/QA/35 was retrofitted with the SIKO Retrofit System.

The machine is owned by Staufer Holz GmbH, where it is used for finishing of specific rectangular furniture elements made of medium density fiberboard (MDF) or particle board. The particular products are desk tops, kitchen cabinet doors, and cabinet doors and shelves in raw formats with uncut ends. The working width of these products ranges between a minimum of 230 mm and a maximum of 3500 mm, and their workpiece thickness ranges between 10 mm and a maximum of 60 mm. In addition, rectangular sound-proofing elements for wall and ceiling cladding can be formatted and processed with this machine. All plates are rough-cut to size before being processed by the machine. The bleed margin before production is 10 mm on each side.If a workpiece passes through all steps of the machine, it will acquire the finished final dimensions at the end of the process.

Application-Specific Requirements

The application-specific request included the replacement of the manual size changeover of the axes by means of automatic actuators on four universal milling cutters and two standard milling cutters. Before the upgrade, the existing control system did not offer the possibility of automatically controlling the drives. As part of this upgrade, no new programmable logic controller (PLC) for the overall machine was to be installed. This would have required the machine to be decommissioned for a long time and thus resulted in a significant loss of production. Also, the investment cost would have been very high.

The specification was to install an economical and functional control system, which would control the size changeover drives while maintaining the existing machine controller. However, the controller needed to be able to communicate with the automatic size changeover mechanism. Another challenge for EUROTEC International was the construction of the “coupling,” which integrates the actuators to the previously manual axis adjustment mechanism. The object was to ensure adequate fastening and to provide a flawless and clearance-free transmission between the actuator and the adjustment spindel. Due to the complexity of the workpiece product profiles, the size changeover mechanisms must be very precise. Staufer Holz has a number of different product profiles for this machine, which are used in the processing of various work pieces. The machine processes workpieces with motor-driven saws and cutters to which different edge radii and groove, spring, and seam profiles are applied.

Initial Situation

A total of six adjustable machining units are located on the double-sided formatting and edge banding machine, three on each side. They are arranged one after the other along the approximately 12 m long machine.

The arrangement of the optimized processing units can be represented as follows:

| Left: | Standard milling cutters - universal milling cutters - universal |

| Right: | Standard milling cutters - universal milling cutters - universal |

The workpiece is machined at two opposite sides in each pass. If the workpiece requires processing on four sides, it needs to be turned 90O after the first pass before it can be reloaded into the machine. Four-sided processing also requires a size changeover even when working on a single workpiece, because the workpiece is rectangular and the format has two side lengths. The width would need to be adjusted.

Manual Adjustment

Before the retrofit upgrade of the machine, size changeover was performed manually. The operator transferred the order-related production data from the order document manually to the machine. He had to make adjustments on two axes for each processing unit, horizontally and vertically. Horizontal adjustment was necessary because the tools have different diameters. Vertical adjustment was necessary because the individual tools have different heights and their position needs to be adjusted before they are used. Axle adjustments were done for each processing unit via adjustable spindles with counters, by which the adjustment values were checked visually. The spindle was equipped at the top with an attachment onto which fit a ratchet that was used by the operator to do the actual size changeover.

Optimization Potential

Performing manual adjustments on 12 axes with this machine was a very error-prone and time-consuming process. Individual errors were introduced while transferring the production specifications onto axes to be adjusted (incorrect axis / correct value) or when incorrect settings were not noticed (incorrect value / correct axis). Workpieces run through the machine at a feed speed of 20-24 meters/minute, resulting in an average processing time of about 30 seconds for each workpiece. Because of these and other potential sources of error, the waste rate with multiple size changeover was very high.

The optimization potential at Staufer Holz GmbH can be quantified by the number of size changeovers performed. About 15 to 20 size changeovers have to be made per eight-hour shift. Each manual size changeover takes about 10 to 15 minutes. In other words, there is a production loss of about two hours per shift as a result of manual size changeovers. In a (theoretical) three-shift operation this would be a total of about six hours of lost production.

Against this background, the required solution had to realize the following objectives:

- a reduction in the time required for a size changeover,

- waste

- sources of error in the processing of orders

and produce significant savings.

The SIKO Retrofit System with ETC5000 meets these conditions. The “turnkey” system solution for efficient axis and spindle monitoring and adjustment includes all necessary components and is tailored to individual requirements. The system modules ensure

- higher machine efficiency with reduced downtime,

- significantly higher process reliability through controlled and fully automatic format adjustment,

- high reproducibility as a result of automatic variance compensation and,

- an acceleration of system integration through operational HMI

- (Human Machine Interface) in the form of a “plug and play” touch panel ETC5000

Target State

The moving parts of the HOMAG machine have a weight of several hundred kilos. The physical labor required for manual adjustments is therefore rather demanding. A spindle revolution follows a four millimeter path. If 10, 20, or 30 mm have to be adjusted, it will take a correspondingly long period of time to perform.

The following is recommended for the use of SIKO retrofits: The more frequently an axis needs to be adjusted, the more productive and revenue-generating a controlled or automated positioning solution will be. When a size changeover needs to be executed only rarely, then mechanical or fieldbus position indicators often suffice. However, if multiple size changeovers have to be made on a machine, for example, one format adjustment per hour, then actuators are worthwhile.

The individually configured SIKO retrofit package for the HOMAG machine therefore consists of

- ETC5000 Easy Touch Control, including ready-for-operation control software,

- field peripherals, in this application, AG05 and AG06 actuators,

- an IO20 bus-compatible DIN rail module with 8 digital inputs and outputs for the assessment and control of external sensors and actuators,

- and the necessary accessories such as cables, connectors, etc.

Four AG05 actuators were used for the standard milling cutter aggregates. A total of eight AG06 actuators are installed on the universal milling cutter aggregates.

AG05 – ensures reliable and precise size changeovers in existing machine installations as part of the ETC5000 retrofit solution.

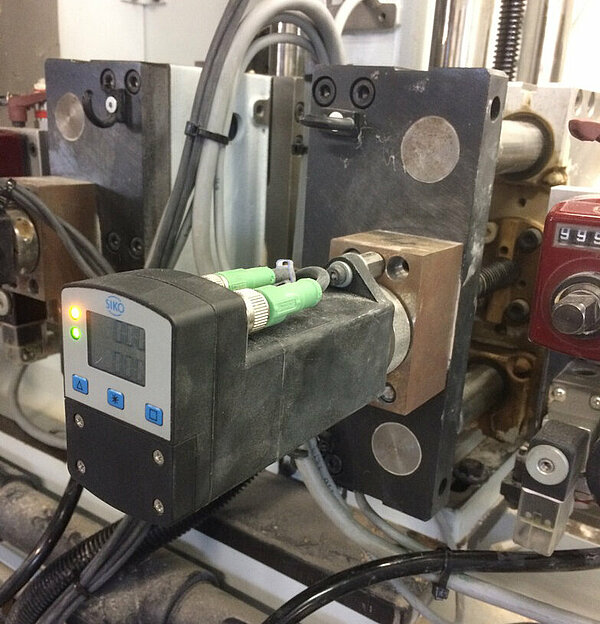

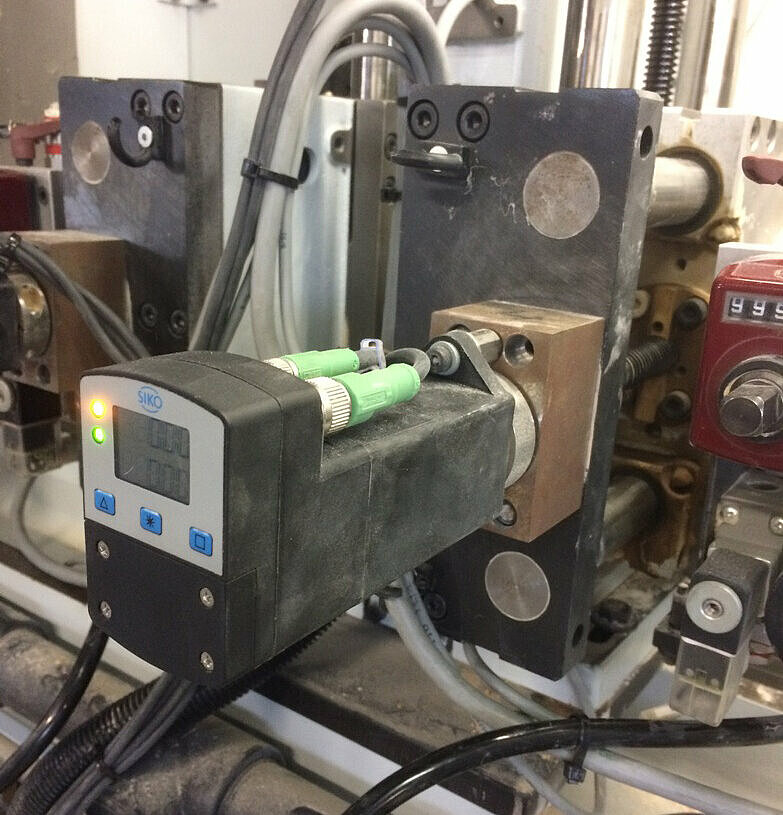

Modular components of the individual SIKO retrofit solution: AG05 and AG06 actuators and BUS cable, as well as ETC5000 control software (not in the picture), touch screen for operation, and IO20 interface

While upgrading the machine with the SIKO retrofit system, all axes were converted to NC axes (NC: Numerical Control). The numerical control ensures ETC5000 control software. The ETC5000 is operated via a touch screen. This is what EUROTEC International used to do the parameterization for each axis before commissioning, including, for example, the shaft pitch configuration. This basic configuration is required so that the system knows the distance covered by each axle after a complete spindle revolution. On the HOMAG, one spindle revolution corresponds to four millimeters. Another parameter defines whether increasing values are set when the spindle rotates clockwise or if it is turned counter-clockwise. The individual product profiles were created after completion of parameterization. EUROTEC assisted the operator when applying the first product profile. Subsequently, this activity was carried out by the operator. After four months of operation, approximately 50 product profiles were in the system. This result demonstrates the intuitive operation of the ETC5000 via touch screen and proves that the system is easy to operate.

The individual product profiles can be selected with the ETC5000 touch screen. After selection, they are sent in the form of control instructions to the actuators and execute movements and axle adjustment on the individual work stations as predefined in the corresponding profile. The actuators go into position simultaneously and remain in this position with an independent position control until a new instruction is sent from the ETC5000 to the actuators. This process, the actual size changeover, takes a maximum of 2.5 minutes.

To achieve this operational status, EUROTEC had to implement yet another mechanical requirement. To this end, adapters were made to facilitate the mechanical coupling between head stock flanges and actuators for all 12 adjustable spindles.

Communication between the main machine controller and the actuators, sensors, and ETC5000 is managed with an IO20 DIN rail module. The IO20 works here as a “link” to report back the ETC5000’s pre-defined recipes or profile conditions to the main controller. One condition is that the machine is only enabled to start if it is actually loaded with wood. This machine condition check is carried out using light barriers. If wood is located in the machine, the light barrier is interrupted. The IO20 signals an “OK” to the machine control, the green light comes on, and the machine starts production. The IO20 makes the ETC5000 an open system so that it can communicate with other devices and components.

Target Validation

- Time Requirement

The time required for a size changeover has been reduced from 10 to 15 minutes to about 2.5 minutes with the SIKO Retrofit System for automated format adjustment. Now when size changeovers are needed the operator can handle other required work, such as procurement of new material, and does not have to do it manually. The average process speed increase is estimated to be 300%.

- Waste Material

The waste rate was significantly reduced because incorrect settings are not possible with system-compliant operation. The ETC5000 ensures continuous monitoring. During manual size changeovers, continuous material consumption was incurred while checking the settings on the workpiece before the actual customer order could be run on the machine. When using the SIKO retrofit such waste is close to zero. Material consumption as a result of the setting is virtually eliminated, and operation of the machine is considerably optimized. Orders can be run immediately after the size changeover.

- 3Sources of error in the processing of orders

With the SIKO retrofit, the machine is not exposed to any individual error sources. Those sources of error used to manifest before the retrofit as a result of different skill levels of operators, for example, and affected production quality. Using the ETC5000 the machine now reproduces quality and competence systematically at a high level and ensures a stable production process and homogeneous product quality..

- Precision

The SIKO Retrofit also results in increased accuracy. The workpieces have to be parallel and at perfect right angles. This is crucial especially for the four-sided machining of workpieces. For the HOMAG machine, a theoretical accuracy of one hundredth of a millimeter (0.01 mm) was calculated after the retrofit. This value surpassed the target. In other words, positioning of the actuators with the ETC5000 is more precise than required and almost impossible to achieve with manual size changeovers.

Additional Benefits

There is another benefit for Staufer Holz after the retrofit of the HOMAG machine. ETC5000 ensures continuous position monitoring of actuators. If the position of the actuators changes for unknown reasons so that they are outside the specified tolerance limits, the system will initiate an audio-visual warning impulse via the IO20 and send it to the machine’s controller. The machine stops, the alarm sounds, and a red light comes on. In this particular case, the ETC5000 provides system monitoring and makes a major contribution to business value because it detects faulty machine settings in time, stops orders on time, and therefore prevents expensive waste of material.

The SIKO Retrofit System convinced EUROTEC International with its holistic approach. It provides all the necessary components from one source. The solution can be customized and tailored to individual needs one hundred percent depending on the application. Crucial to EUROTEC International’s decision to equip the HOMAG machine with the SIKO retrofit components was the excellent installation compatibility that the system provides. All system modules used in the solution can be adapted to the respective axel geometry. EUROTEC benefited from this system property as well when converting the HOMAG machine. On the other hand, there may be changes in the production process at Staufer Holz in the future which will also affect the HOMAG machine and require modifications. The machine has a wide range of adjustment options that are not currently being used. Machine attachments where adjustment axes can be added are also conceivable. The ETC5000 is suitable for this purpose as well. It can adjust up to 31 axes. Currently 12 axes are being adjusted via the actuators in the HOMAG application.

The SIKO Retrofit System ETC5000 is self-sufficient as a stand-alone solution. It does not have to be physically integrated into the existing machine control system. Nevertheless, the SIKO retrofit peripherals essentially comprise an open system. Therefore applications are conceivable in which the retrofit peripherals could be integrated into existing control systems; the actuators would then be controlled by the actual machine controller. Staufer Holz’s machine already has a controller. To increase ease of use, it would be possible to integrate the systems and control them with just one console, rather than two

The AG05 and AG06 actuators used in the SIKO Retrofit System are tested in accordance with protection classes IP65 and IP54. Fat and oil in conjunction with wood dust and sawdust can cause gumming or bonding which affect the proper functioning of the machine. In the majority of such or similar cases, the actuators can run themselves clean because of their powerful torque, the AG05 actuator with a maximum of 5 Nm at 50 min-1, AG06 with a maximum of 13 Nm at 15 min-1. Otherwise, the ETC5000 shuts the machine off in the unlikely event to protect man, machine, and workpiece, and prompts the operator to take appropriate countermeasures with an issued maintenance instruction. This additional service function was previously not available in this form for manual size changeovers.

Author: Christian Fischer, SIKO GmbH

Characters: 15,588

Characters with spaces: 17,935