Magnetic encoders: Robust technology with many strengths

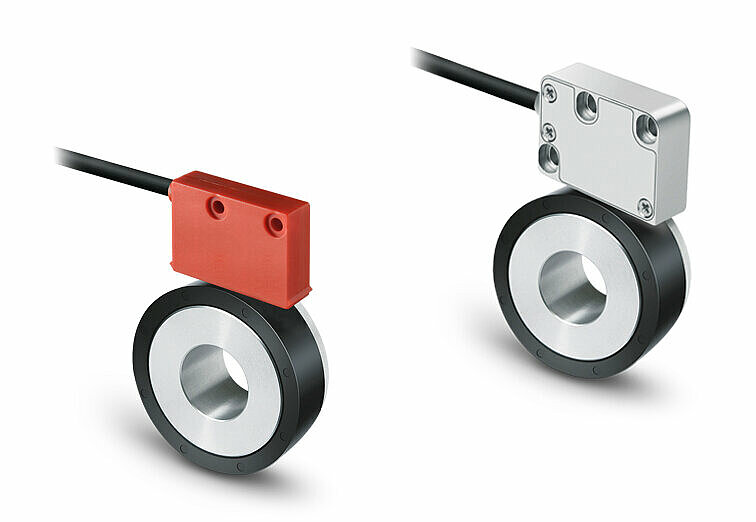

Magnetic encoders are known for their robustness and cost efficiency. Compared to optical sensors, they are characterized by their wear-free, contactless operation and their insensitivity to contamination. These advantages result in low maintenance requirements. They are also more flexible when it comes to installation. In contrast to optical measuring systems, the distances between the magnetic encoder and the belt can be significantly greater. The available versions include

- A wide range of sizes down to a PCB solution (PCB design)

- Individual connector designs

- Installation in customer-specific housing

Incremental and absolute measurement technology for magnetic encoders

The choice of a suitable encoder begins with the decision for a measuring method: incremental or absolute. As a rule, incremental displacement measurement is more cost-effective. Here, a magnetic tape is coded with regularly arranged north and south poles. The pole length determines the maximum resolution and system accuracy. A sensor head moves over the tape at a defined distance and reads the magnetic fields, which are processed as square-wave signals (counting pulses). Counting the pulses makes it possible to measure the distance traveled.

Magnetic absolute measurement uses a two-track tape, with an incremental track on one side and absolute coding on the other. The absolute coding only occurs once on a certain length of the tape. This enables the encoder to know exactly where it is, even in a de-energized state. In the event of a power failure, a reference run must be carried out in the case of incremental measurement to reset the encoder to a specific reference point and report this to the controller. SIKO provides quasi-absolute encoder solutions that temporarily store the measurement information via a battery so that referencing is not necessary even in the event of power interruptions. This is particularly important in medical and analysis technology.

Magnetic encoders are used in various industries, especially in environments where contamination and stress can occur:

- Cobots, industrial drive technology, motor and gearbox feedback, tubular film packaging

- Computer tomographs, solar power plants (suntracking), woodworking, stone cutting

- AGVs, forklift trucks, water jet cutters, stone and metal processing

- Tire balancing machines, elevator technology, pipe bending technology, access controls

- We are happy to develop customized or brand-label encoder solutions for you on request. Get in touch with us!

- You can find out more about SIKO's magnetic encoder technology on the "MagLine Fundamentals – Advantages and Application of Magnetic Encoders" page.