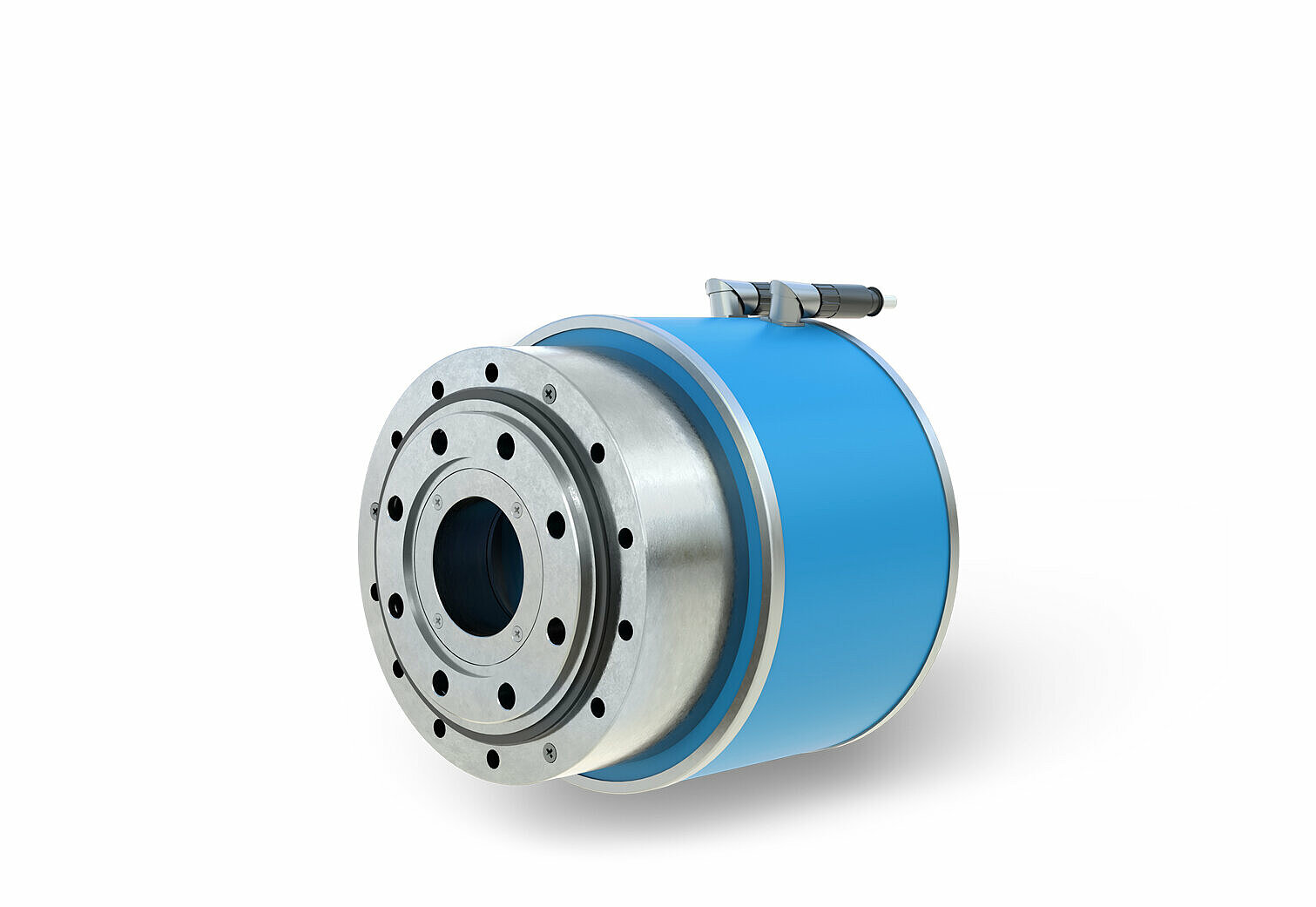

Encoder-based feedback solutions for motors

Precise and reliable control is essential for electric drives in industrial automation. The non-contact encoders from SIKO measure the position and speed of motors and transmit these output signals to downstream electronics. This in turn regulates the speed, direction and precision with which the motor should move.

You can find out more about our magnetic encoders on the page "MagLine Fundamentals – Advantages and Application of Magnetic Encoders"

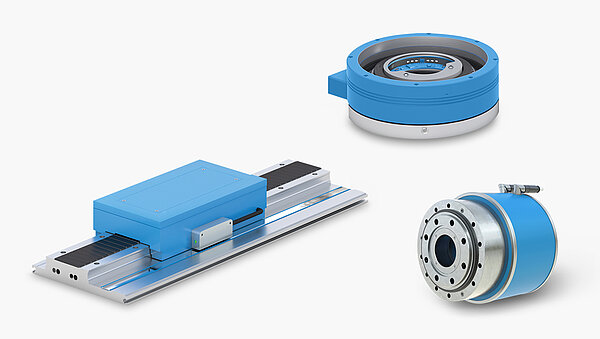

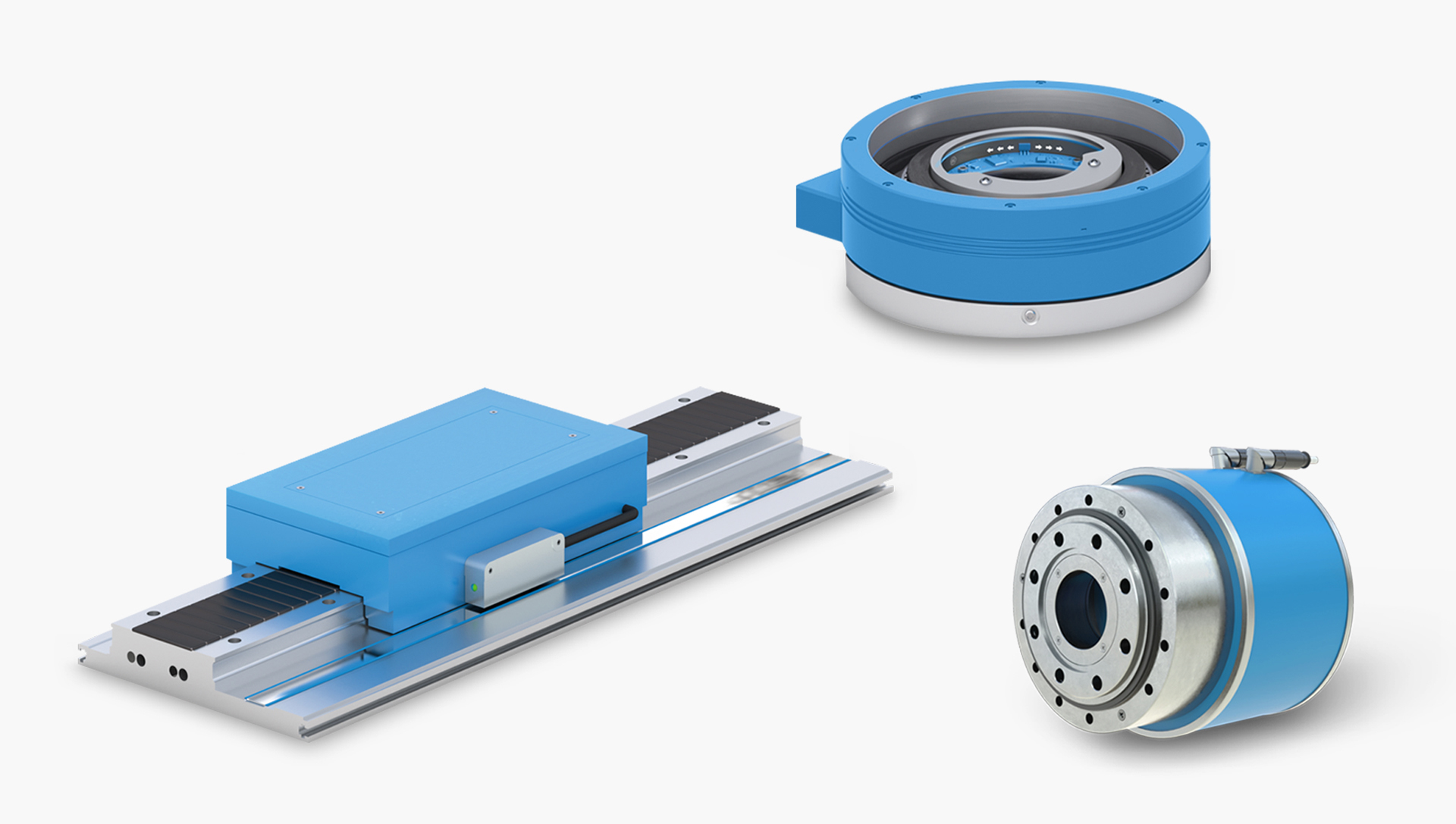

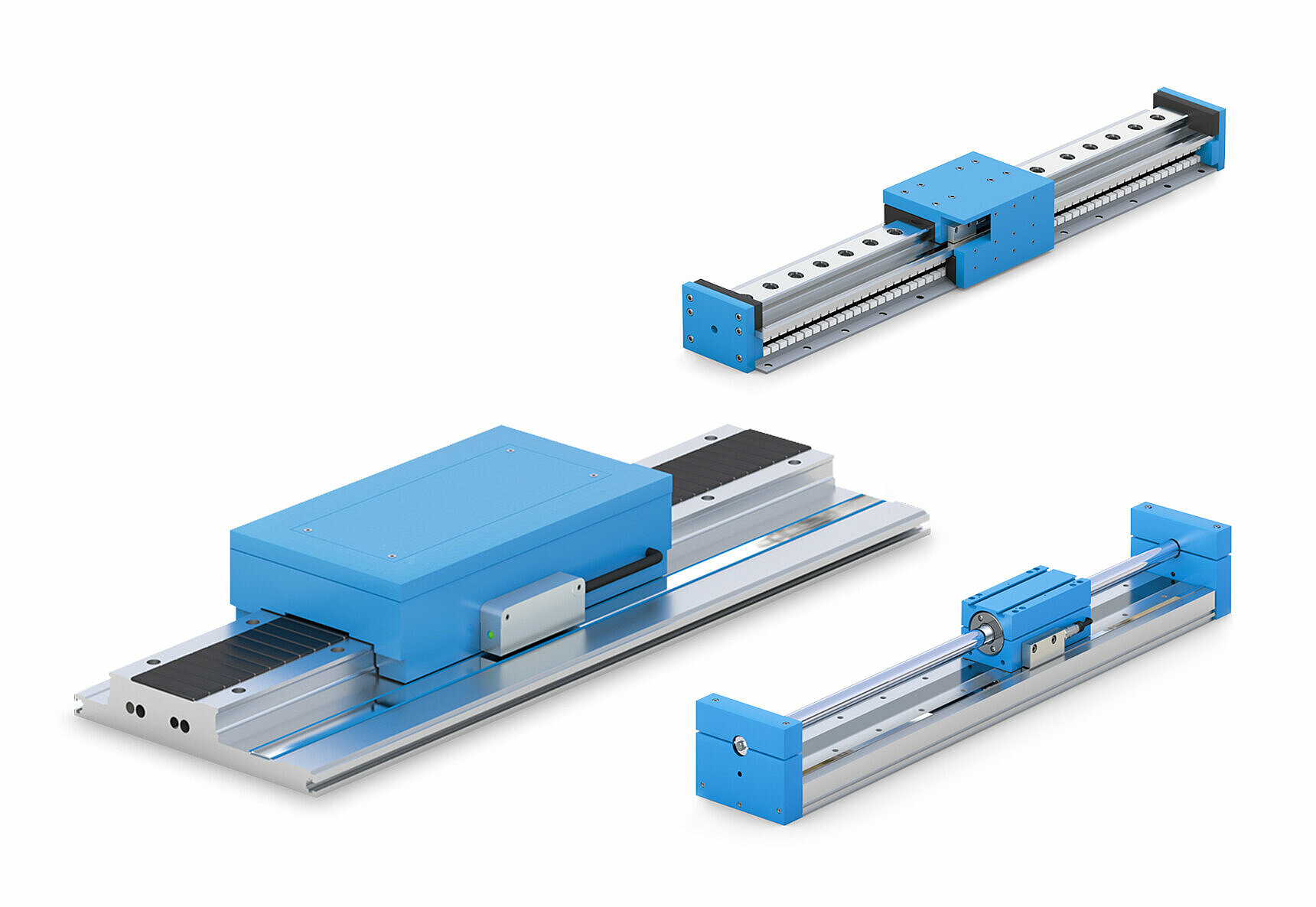

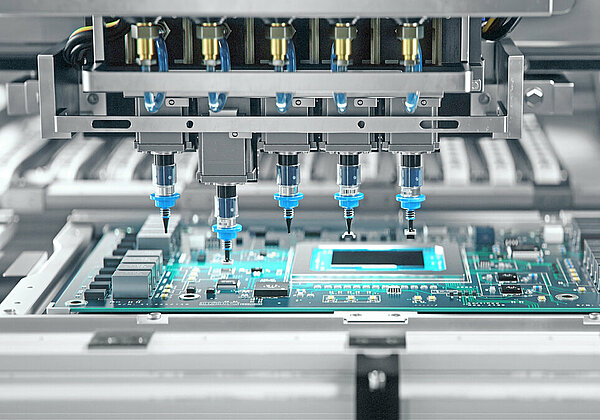

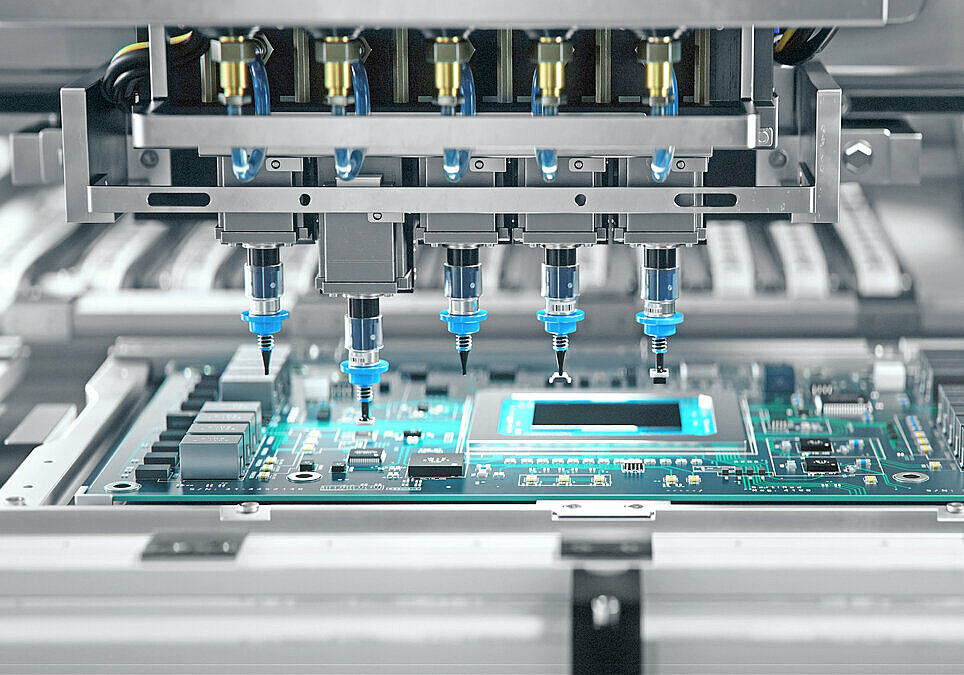

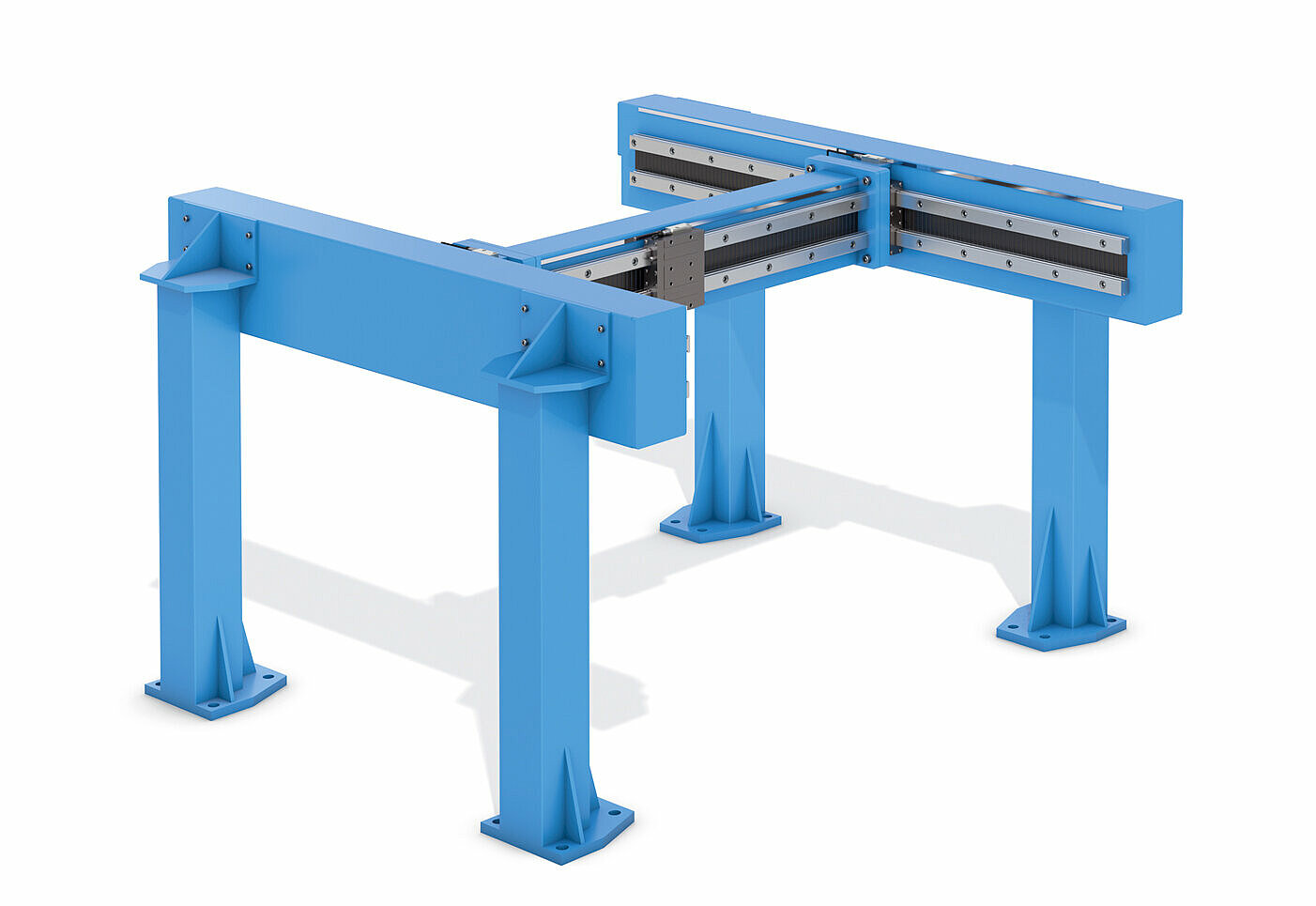

Encoder-supported solutions for assembly and handling technology

High precision in the positioning and placement of components and workpieces is crucial in assembly and handling technology. Even small deviations can result in errors and affect product quality. In addition, a high cycle rate is often required to increase production speed and maximize production capacity. Efficient handling systems are therefore essential, and SIKO's precise encoders meet these high requirements.

Find out more about our magnetic encoders on the page "MagLine Fundamentals – Advantages and Application of Magnetic Encoders"

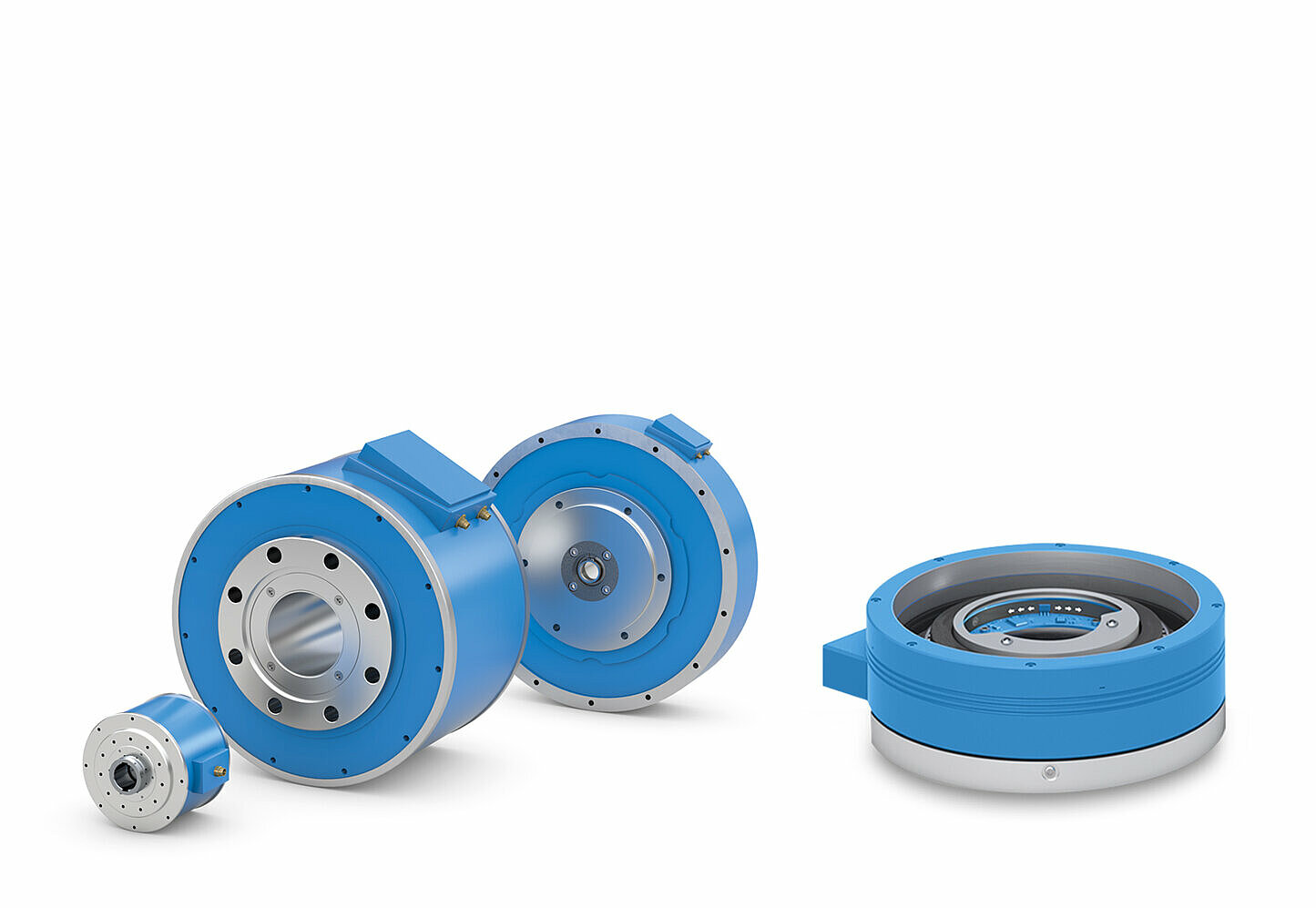

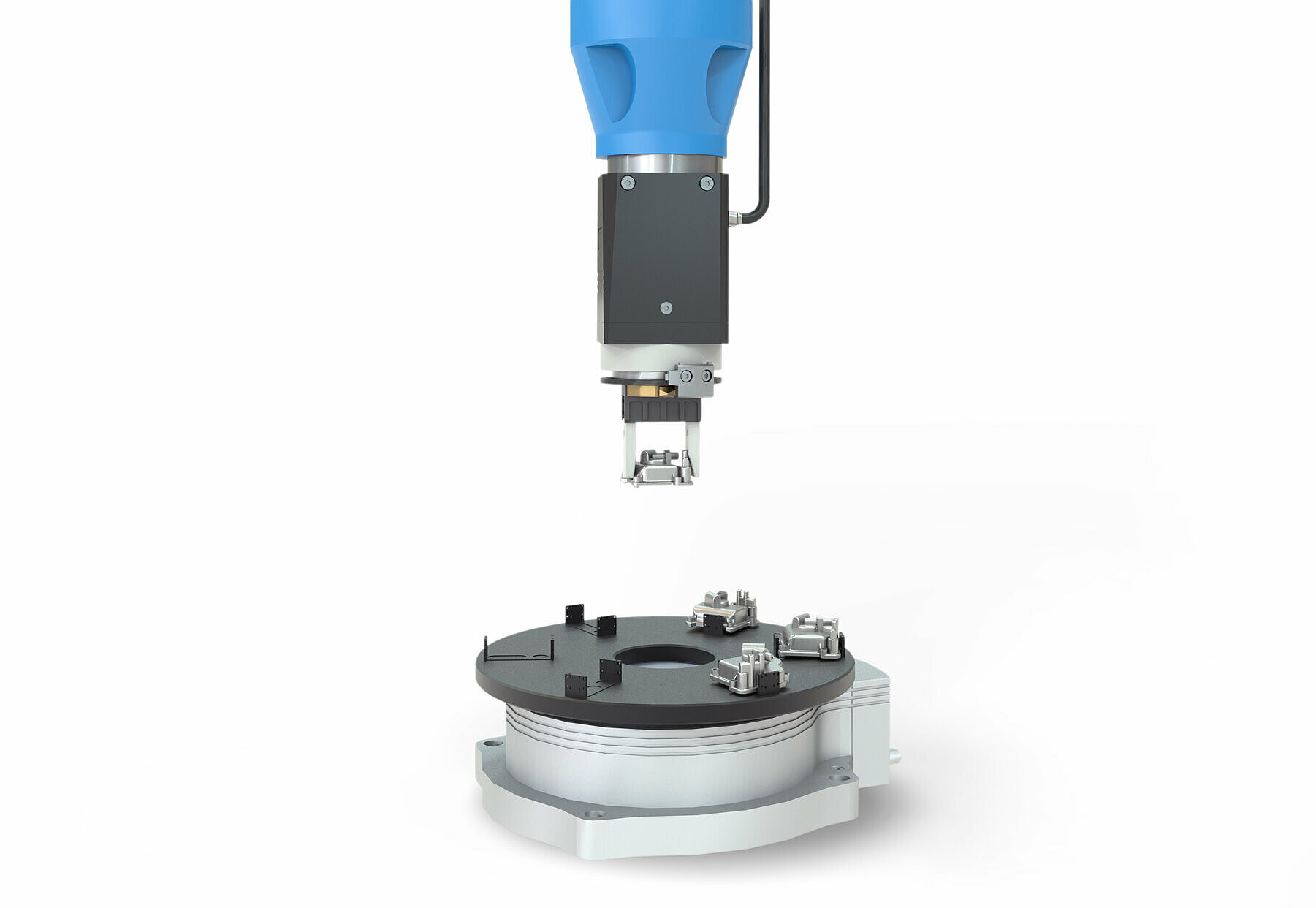

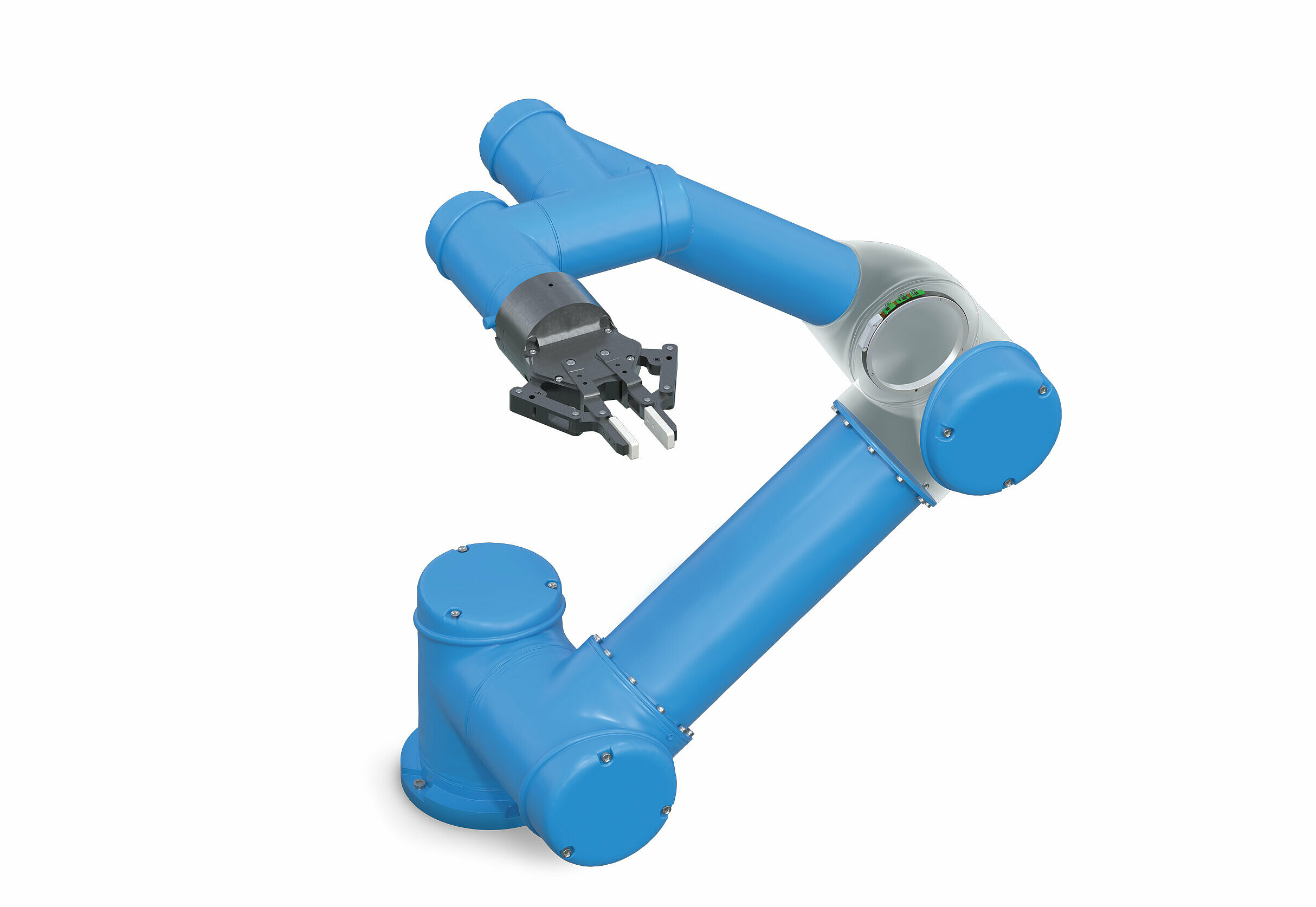

Systems for precise position detection in robots

Precise, safe and efficient motion control of robots requires the use of encoders for position detection. Encoders for robotics must be very small and often be able to be installed without a housing. In addition, the encoders used must be wear-free and low-maintenance. With the non-contact measuring principle of magnetic encoders, SIKO offers the appropriate solution. Customer-specific modifications enable precise integration into the given installation space.

You can find out more about the advantages of magnetic encoders from SIKO on the page "MagLine Fundamentals – Advantages and Application of Magnetic Encoders"