Magnetic length and angle measurement with SIKO MagLine encoders

SIKO's robust magnetic encoder systems have been in use for decades in the field of position, angle and speed measurement. SIKO MagLine systems consist of a magnetic encoder with coded magnetic tape as a linear measuring system or a magnetic encoder and magnetic ring, or magnetic tape as a rotary measuring system.

The special advantages of the MagLine magnetic length and angle measurement technology

- Contactless measuring with magnetic encoder and magnetic tape or magnetic ring :

- Completely wear-free

- Insensitive to dust, chips, moisture, oil, grease, etc.

- Very robust when exposed to shocks and vibration

- No measuring errors caused by gear ratios or gear backlash

- High system accuracy and reproducibility

- Easy handling and installation (video)

- Durable and economical

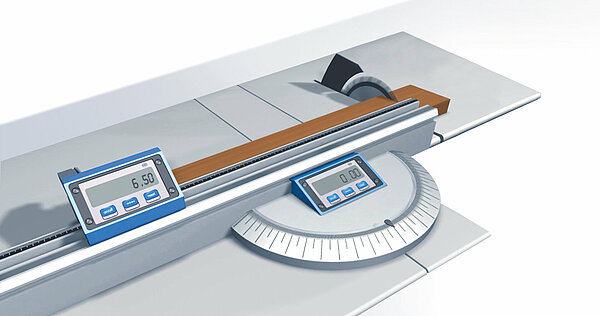

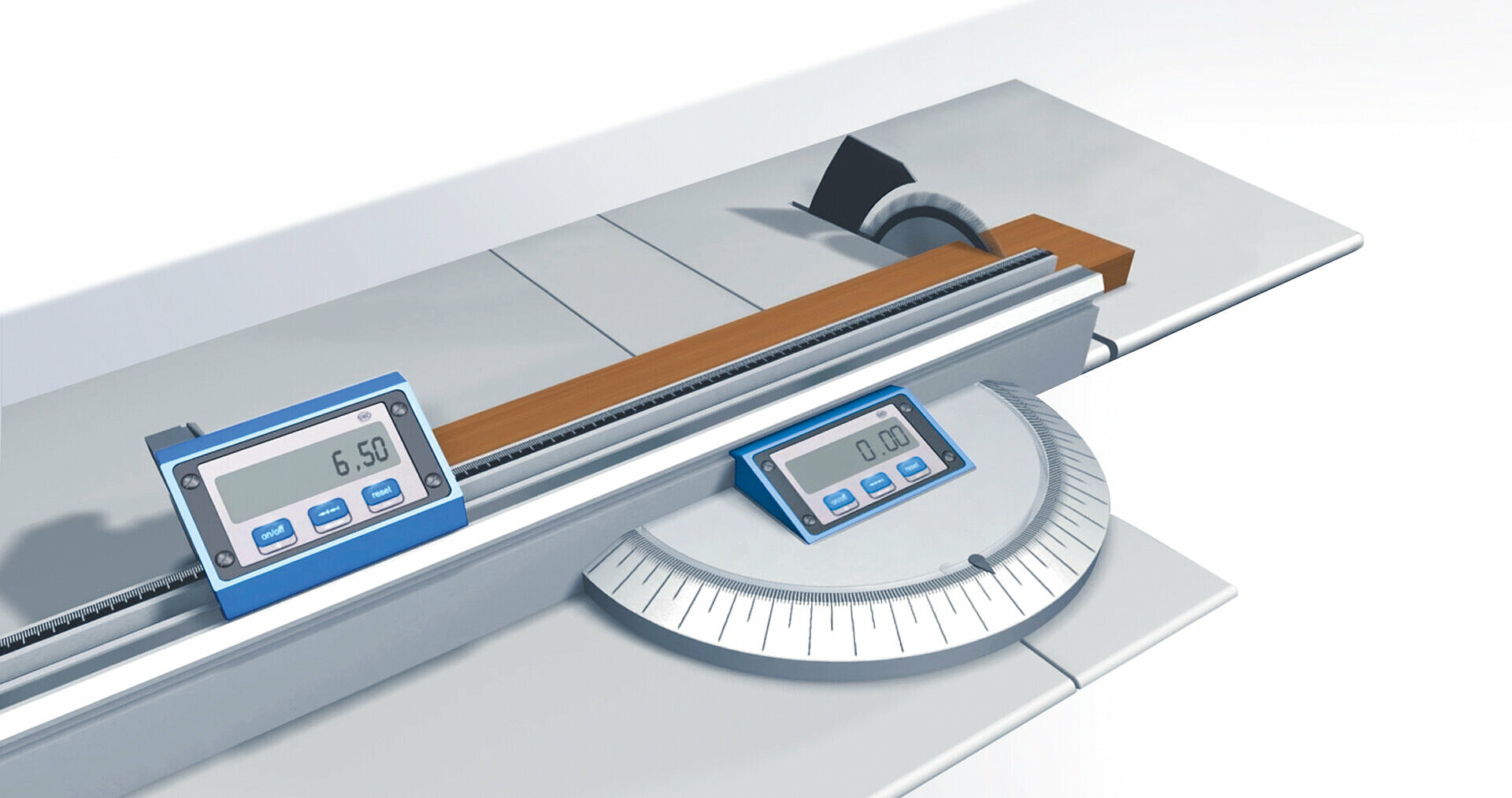

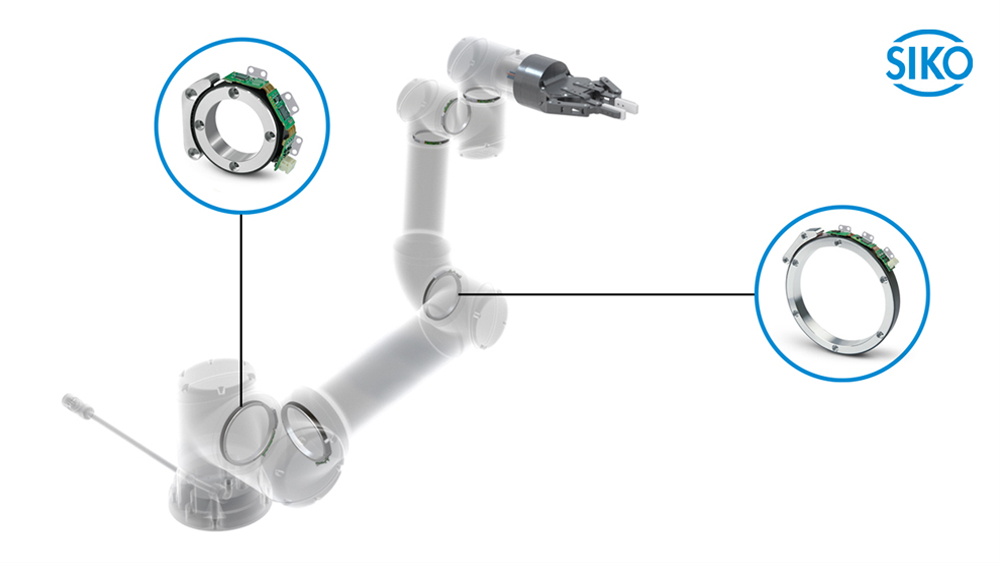

Measurements under extreme industrial conditions are demanding when it comes to ensuring reliability and reproducibility. MagLine systems are the preferred solution for linear and radial positions as well as precise measurement of speeds and angles. Regardless of whether Drive Technology and Robotics or especially soiled environments, such as in Woodworking, the contactless technology makes full use of its advantages.

The magnetic encoder technology defies many different kinds of soiling and mechanical stress in industrial applications. The greatest advantage is the magnetic measuring process itself, since it cannot be negatively affected by typical machine impact (vibration, shock) nor by other influences (solids or liquids). Demanding conditions need robust technology.

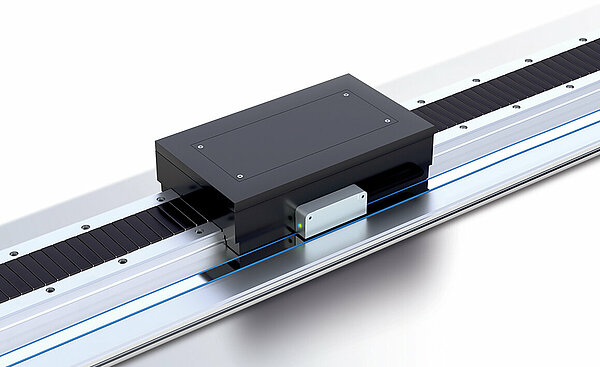

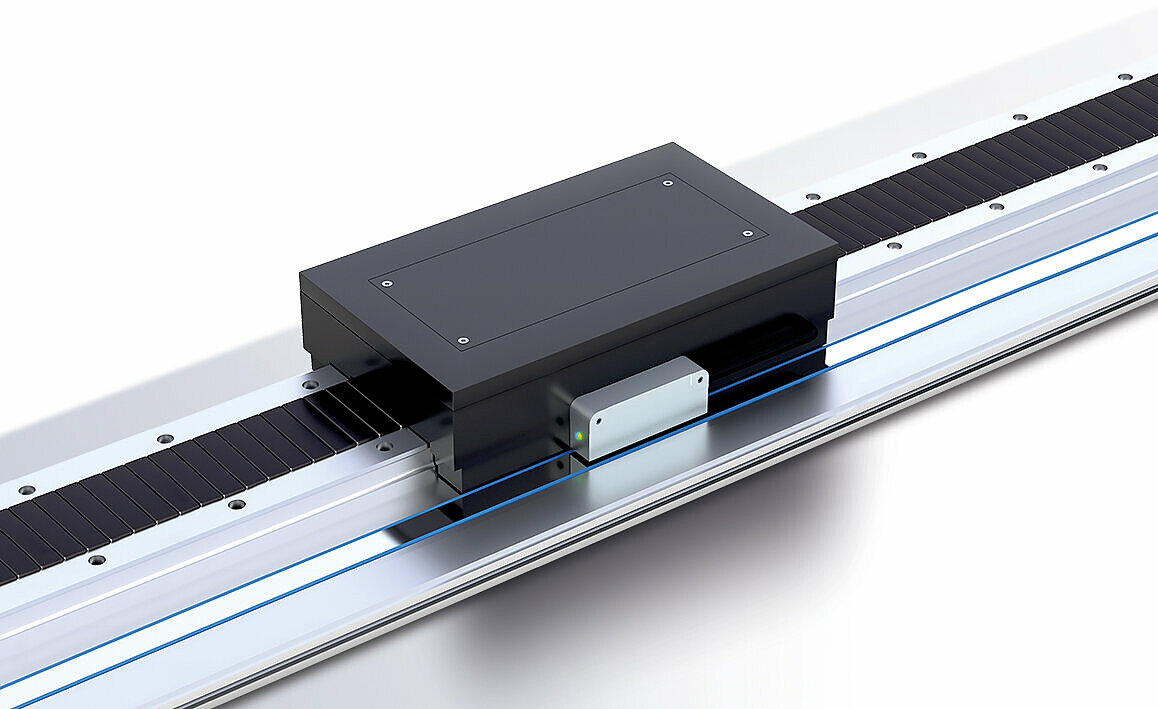

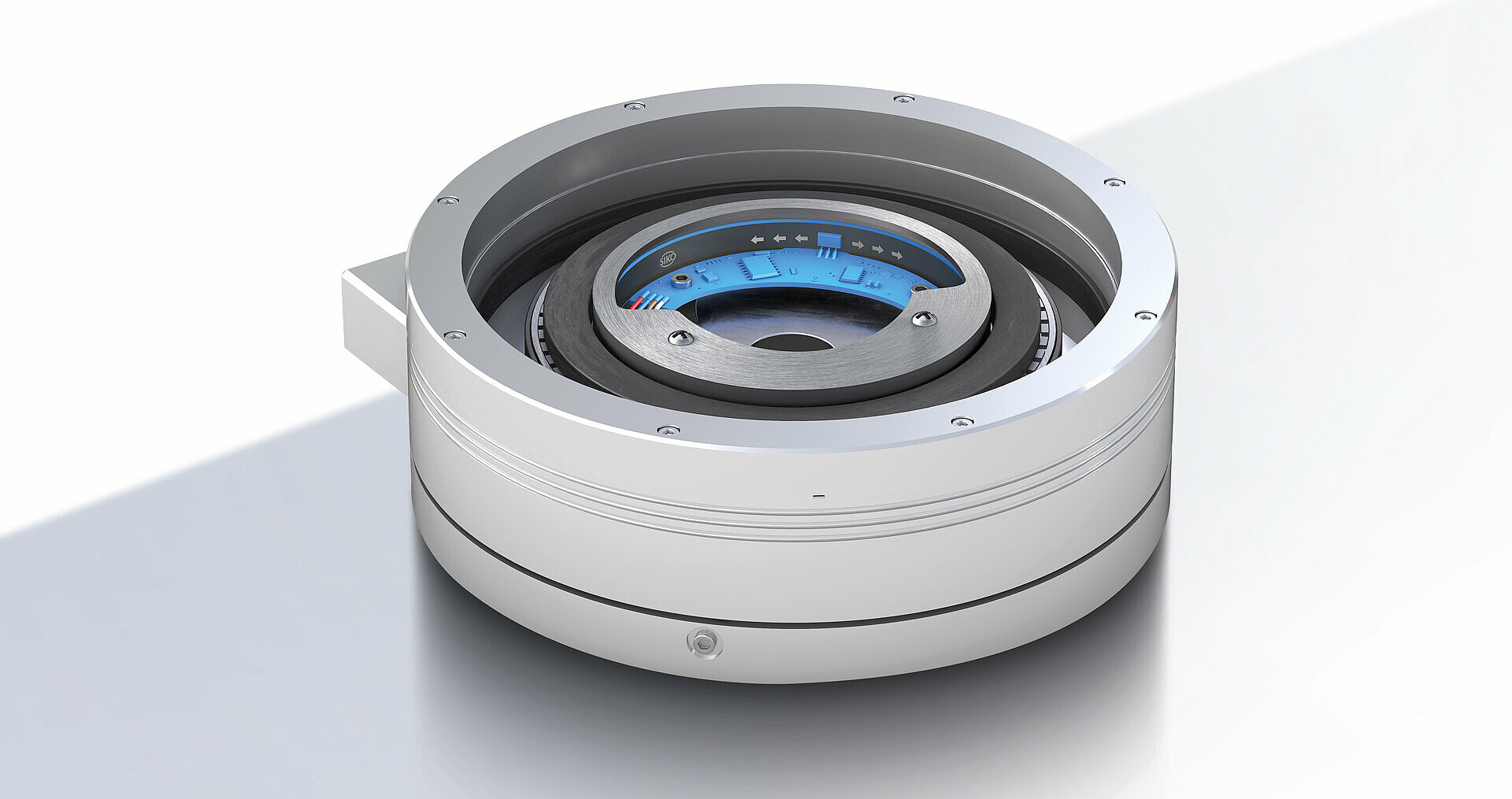

Durable materials and functional units guarantee reliability. To do justice to the mechanical demands, the flexible encoders can be additionally protected by a stainless steel cover strip. The magnetic sensors themselves do not have any moving parts, because the electronic components are fully encapsulated. Robust plastic and metal housings are mainly used to this purpose. The installation of the encoder systems is simple; see the video "SIKO MagLine Easy Installation".

From the idea to the solution

MagLine pursues the idea of replacing mechanically acting measuring systems, consisting of rotary encoder, rack and pinion, with a non-contact system on a magnetic basis. To date, four product groups cover the entire range of industrial measurement tasks. Essential distinguishing features are accuracy, resolution and the reading distance. MagLine's magnetic SIKO technology is the first choice in terms of precision, reproducibility and, above all, robustness of the measuring processes. The main areas of application are the acquisition of linear and radial positions, angle values and rotational numbers.

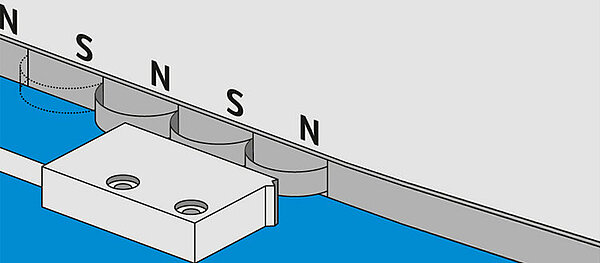

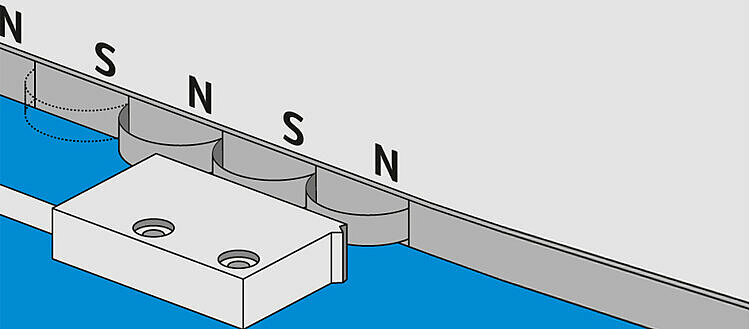

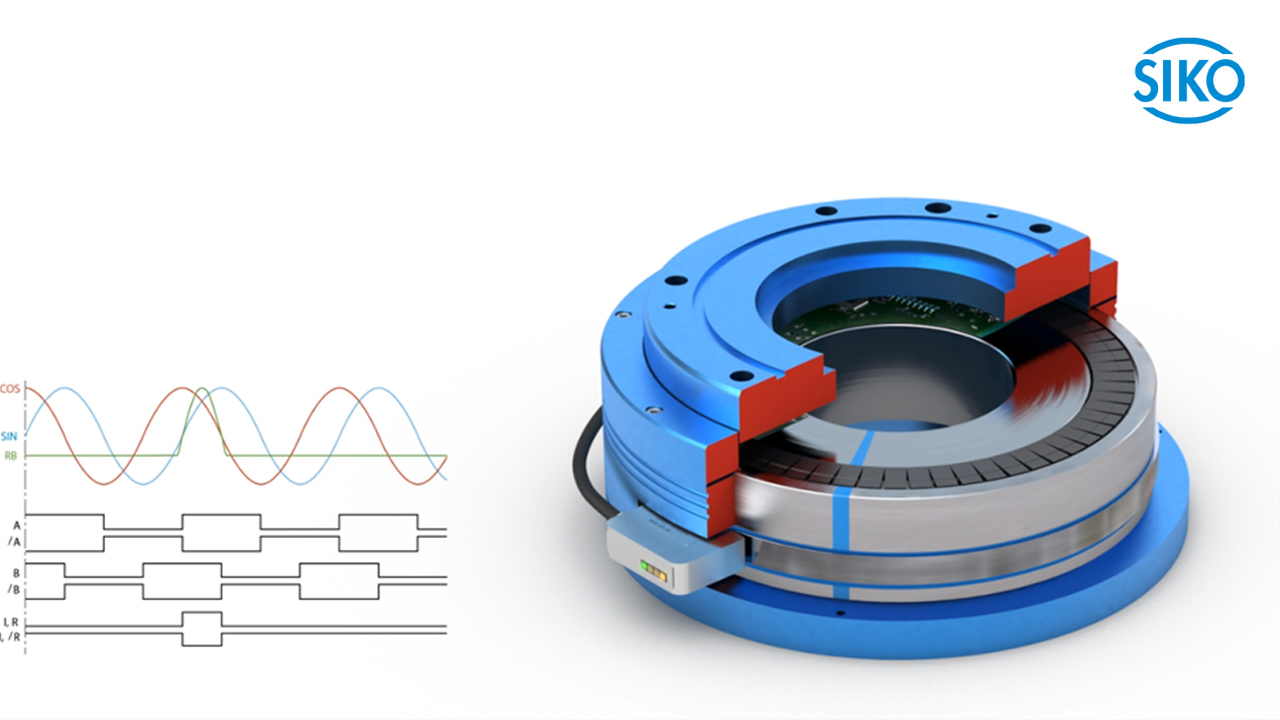

The Magnetic Measuring Principle

The core of the magnetic measurement is a fixed magnetic tape (also called a scale). This tape is contactlessly scanned by an encoder that is fastened to the movable part of the respective machine. The encoder converts the measured values into digital or analog signals via integrated electronics. These signals are optionally available for evaluation electronics, higher-level controllers (PLCs) or measurement displays connected directly on site.

The actual magnetic measurement results from the change in resistance due to magnetic influence. The magnetic tapes are coded in specially developed processes at SIKO. The resulting tape codings enable incremental or absolute measuring methods with different fineness resolutions.

Operating Conditions

MagLine systems can be mounted directly on the positioning or machining process and thus prevent, for example, measurement errors that may arise due to gear play or spindle tolerances.

The reading distance (distance encoder/tape) has a large tolerance range. It can vary over the entire measuring range and within the defined limits (e.g., due to radial run-outs or imprecise guidance). Accuracy and Reproducibility of the position values do not deteriorate as a result.

The robust measuring equipment withstands soiling and mechanical stress in industrial applications. The greatest advantage is the magnetic measuring process itself, since it cannot be negatively affected by typical machine impact (vibration, shock) nor by other influences (solids or liquids).

Demanding operating conditions require robust technology. Above all, the durability of the materials and functional units used guarantee reliability. To do justice to the mechanical demands, the flexible magnetic tapes can be additionally protected by a stainless steel cover strip.

The sensor technology itself does not have any moving parts, because the electronic components are fully encapsulated. Robust plastic and completely metal housings are mainly used to this purpose.

Selection criteria for magnetic encoder systems

- Linear or rotary application?

- Incremental or absolute procedure?

- System accuracy and reproducibility requirements

- Connection to higher-level control systems or autonomous measuring system?

Accuracy class 1 mm – typical resolution 0.25 mm

Tried and tested and technically mature, this product series offers a particularly wide range of coordinated components. The cost-effective solutions open up a variety of individual applications that meet all standard requirements in terms of measurement accuracy.

- Assembly and Handling Technology

- Linear Direct Drives and Torque Motors (Motor Feedback)

- Robotics

- Mobile Automation

- Woodworking

- Metal and plastic processing

- Textile machines

- Machine tools

- Bearing technology

- Medical technology

- Renewable Energy Sources

- Special machine construction