Magnetic sensor ensures safety features in depaneling machines

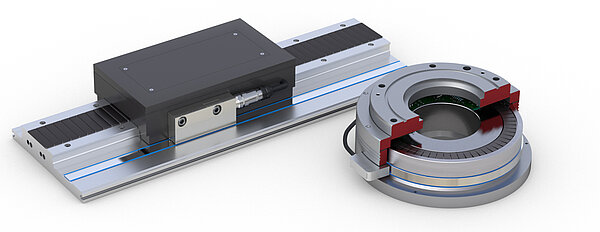

Schunk Electronic Solutions is a component manufacturer (linear units) and producer of various mechanical engineering solutions in which linear motors are used. Depaneling machines require high precision and process reliability when milling and sawing the sometimes minuscule PCB elements. Workpiece and milling cutter positioning must be absolutely accurate.

This is ensured by SIKO GmbH’s MagLine absolute magnetic measurement systems. Stefan Weiner, part of drive technology development at Schunk Electronic Solutions, describes the previous manufacturing situation: “In our depaneling machines, we work with a Siemens controller which is based on the proprietary Siemens DRIVE-CLiQ interface. However, the SIKO absolute magnetic measurement system that we used in the past was not compatible with this as it was designed for SSI technology. We had to work with converters that processed the signal for DRIVE-CLiQ. This required a great deal of wiring in the machine as the connection boxes cannot be more than three meters away from the axis – and consequently led to additional costs.”

New: the first magnetic sensor with safety certification

Schunk was looking for a simpler and more cost-effective solution. Partnered with SIKO, they developed the sensor solution on the basis of the Siemens DRIVE-CLiQ interface. What makes DRIVE-CLiQ technology special is its SIL capability, which means that the interface allows required safety features to be implemented. Continued development resulted in the SIL2-certified MSA111C magnetic sensor with DRIVE-CLiQ functionality. “A unique selling point,” says Andreas Wiessler, head of the MagLine business unit (magnetic measurement technology) at SIKO GmbH. “We developed the first magnetic absolute measurement sensor with an open design – that is, where the scale is mechanically separate from all the electronics – and safety certification.” And its use had the desired effect for Schunk. Firstly, this allowed significant cost savings to be achieved, and secondly, the integrated DRIVE-CLiQ functionality simplified sensor commissioning and communications. Converters are completely unnecessary. The SIKO measurement system is connected directly to the controller as a plug-and-play solution. All DRIVE-CLiQ participants are now detected by the inverter and set up in the system automatically, whereas the SSI interface previously had to be manually configured in order to work.

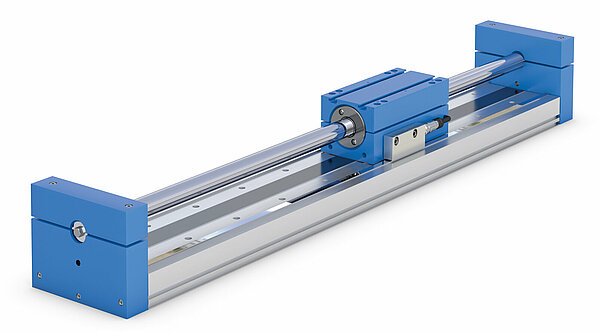

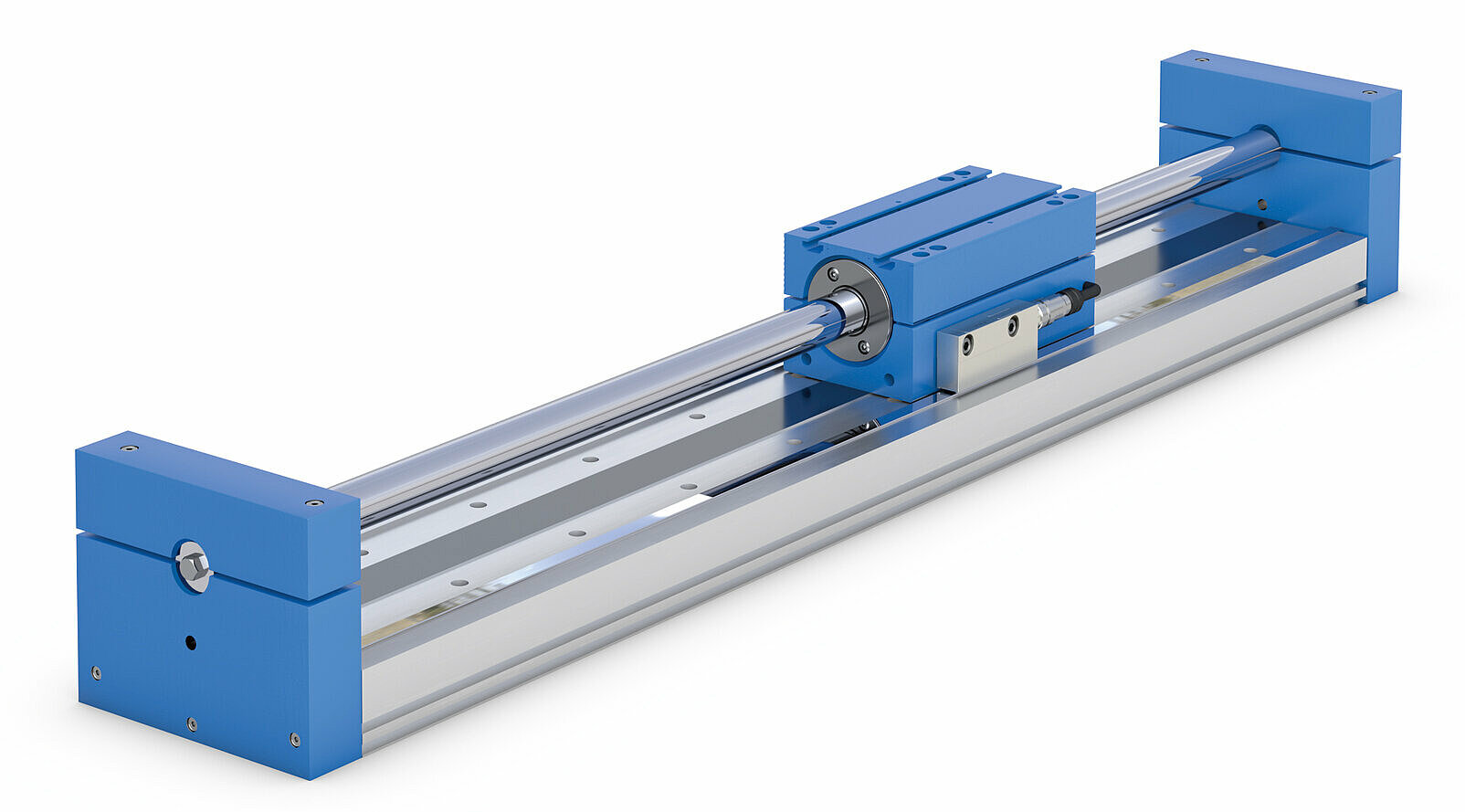

The magnetic sensor performs key in-application safety functions, monitoring position and speed. It is used at various points in the depaneling machine, firstly for determining workpiece carrier positions. The machine is composed of two drawers (shuttle systems) where each workpiece carrier is attached to a linear axis. This axis consists of an X-shaped profile along which the workpiece carrier guide blocks run. PCB panels with maximum dimensions of 350 mm wide and 430 mm long are manually placed on the workpiece carriers. The linear axis conveys the workpiece carrier and panels underneath the milling head. Once there, the axis performs the CNC program’s machining movements in direction Y. The milling head is attached to a further linear motor which handles direction X of the CNC program. To determine running block positions, the X-shaped profile of each axis features a slot on the side into which an absolutely encoded magnetic strip is bonded. The sensor head itself sits in the running block, which moves along the guide containing the strip, scans the positions and transmits the signal to the upstream controller.

Andreas Wiessler explains why an absolute sensor was chosen: “Due to safety requirements, the only possible option for this application was an absolute measurement sensor which can capture actual values at any position and at any time, even without power. When the machine is switched on, the actual position is instantly detected. This eliminates the need for reference runs as required in traditional, incremental systems.”

The fact that the sensor head is not pre-enclosed and fitted on the guide is a major advantage. Instead, we can build the head into our standard DRIVE-CLiQ housing and thereby perfectly integrate the sensor into our axis. Encapsulated sensors would need to be screwed onto the sides, which would interfere with the contours and need to be constantly taken into account later on. In this version, everything is in one piece.

Stefan Weiner, Schunk Electronic Solutions

Certified components simplify safety assessments

First and foremost, safety provisions protect operators. Situations may arise where an operator must intervene in the process, causing a risk of injury. This requires the definition of safety levels such as a reduced speed or a safe position e.g. when the guard door is open. Determining the sensor position enables a dependable extrapolation of speed. Full shutdown capabilities must also be ensured, meaning that if the sensor detects an error (e.g. due to a broken cable, failure of electronic components or motor overheating), this must be relayed to the controller and an immediate shutdown triggered.

The SIL2-certified SIKO sensor guarantees that the signal is always reliably transmitted. If such a machine component is already safety-certified itself, this simplifies the safety assessment process for the entire system. Stefan Weiner explains: “We use the DRIVE-CLiQ sensor as a safeguard, we integrate it into our axes, and we can take its safety characteristics for granted. Once we have taken care of installing the encoder safely in the measurement system, we can define our axes as safe too. This also allows our end customers to easily install safety technology in their applications by purchasing individual components such as linear axes.”

Aside from safety certification, the MSA111C is remarkable for its precision – boasting a system accuracy of ± 10 µm and reproducibility of ≤ 2 µm. The PCB milling mechanisms must be very precisely designed to ensure delicate structures. Aside from position detection, the sensor can also register the temperature of the motor. To that end it has a temperature sensor input which is connected directly to the motor with a temperature probe, enabling the sensor to relay the temperature directly to the controller via the interface

Stefan Weiner praises the small and compact design of the sensor: “The fact that the sensor head is not pre-enclosed and fitted on the guide is a major advantage. Instead, we can build the head into our standard DRIVE-CLiQ housing and thereby perfectly integrate the sensor into our axis. Encapsulated sensors would need to be screwed onto the sides, which would interfere with the contours and need to be constantly taken into account later on. In this version, everything is in one piece.” The maximum resolution of 1 µm is more than adequate for Schunk’s requirements. An optical measurement system would be much more precise and high-resolution, but would also be considerably more expensive and more sensitive to environmental conditions. SIKO’s magnetic system, by contrast, is highly robust and impervious to dirt such as the dust which may accumulate when milling and sawing PCBs in spite of suction mechanisms.

Special custom solutions

The many years of collaboration between SIKO and Schunk have already resulted in numerous successful projects and special developments. The DRIVE-CLiQ sensor was another such custom development, but one that is not just exclusively available to Schunk. The SIKO sensor with SIL2 certification and DRIVE-CLiQ functionality is freely available on the market and can be used in a wide range of motor feedback applications, e.g. woodworking or packaging technology.

For Andreas Wiessler, the safety version of the magnetic sensor is a logical development in the field of motor feedback solutions, especially for direct drives (such as the linear motors here): “In light of the growing awareness of safety applications and increasingly systematic implementation of the Machinery Directive, we are on the right path with safety-certified individual components. This means we can make it easier for our customers to implement necessary safety features.”

Author: Michaela Wassenberg, freelance journalist

Characters with spaces: 8,546